Many big companies utilize supply chain applications in one form or another to manage their supply chains. For some years, supply chain providers have boasted about their efforts in artificial intelligence (AI). Finding vendors with “field-proven AI/ML algorithms” that “have been deployed at scale” is crucial.

Table of Contents

According to Kinaxis chief marketing officer Jay Muelhoefer, optimisation and heuristics perform better for other sorts of planning challenges than artificial intelligence. This article aims to assist practitioners break through the hype by focusing on the many forms of artificial intelligence employed and the types of issues they solve.

A variety of companies are using machine learning to predict new products coming out in the near future, including Infor, Solvoyo, and Lily AI.

The garbage in, the garbage out principle:

The “garbage in, garbage out” problem occurs when the master data on which planning applications are based is inaccurate. The data is updated using artificial intelligence. It’s not simple for an agent to figure out how long it takes for a shipment to arrive from a vendor at a manufacturing facility.

The supply chain optimization models utilized in process industries are far more intricate than those used in other industries. Among core rules are mass balance, energy balance, heat transfer relations, and reaction kinetics. It’s crucial to comprehend yields as well as the energy needs for operating the machinery.

Models for Demand Planning Can Actually Learn:

When a supply chain planning application accepts an output, such as a prediction, it examines the accuracy of the output and then modifies its own model to provide better outputs in the future. The use of artificial intelligence in supply chain planning isn’t new, but it has grown a lot more sophisticated.

The extent of specificity and planning horizon of forecasts today is much greater than twenty years ago. It is far more difficult to predict how many units of a particular product will sell in a given store than the number of units of a product family. Without the current generation of machine learning, this surge in the number of predictions would not be feasible.

With the help of Blue Yonder, Mahindra & Mahindra was able to improve predictive performance by 10%. With a more accurate prediction, you may carry less inventory while maintaining or even enhancing service levels. The improvement in forecasting culminated in a 10% increase in service levels and a 20% reduction in inventory investment.

During the outbreak, they increased safety supplies by 30%. It wasn’t about saving after COVID. The game evolved into a worldwide race for the same set of basic ingredients. The competition intended to get semiconductor chips for this business, which creates automobile replacement components. Forecasting is premised on the theory that history repeats itself.

Demand sensing — the use of various, real-time signals (such as sales at a specific store or shipments from a retailer’s warehouses to their stores) – combined with machine learning, resulted in much lower inaccuracy. Companies who employed these solutions experienced substantially faster improvements in their projections than those that used traditional methods. Several vendors, including QAD Dynasys, are investing in this sort of solution.

A variety of companies are using machine learning to predict new products coming out in the near future, including Infor, Solvoyo, and Lily AI. Forecasting is done using attributes. Attributes include the material, size, color, and price as well as its appearance and price. Encouraging merchandisers to enter the qualities has been difficult since they regard it as a pointless and tedious chore.

The Sustainability Feedback Loop and Machine Learning:

ARC investigates how organisations use supply chain planning to achieve their sustainability objectives. Cyrus Hadavi, CEO of Adexa, demonstrates how the company’s solutions can quantify a plan’s carbon impact. Carbon emissions can be reduced by utilizing these qualities in addition to environmental and governance purposes.

Monitoring the actual emissions following the execution of a plan allows you to determine whether it was accurate. Similarly, a sustainability solution may use machine learning to improve its predictive abilities by comparing predictions to actual sales.

Supply planning also uses artificial intelligence:

When supply strategies don’t work out, it’s usually due to a data quality issue or an unforeseen event, rather than a flaw in the model. AspenTech, for example, employs predictive analytics to forecast when major refinery gear would fail in order to produce alternate production plans.

Use of Natural Language Processing (NLP):

Coupa and Oracle are leveraging AI to analyze supplier risk using natural language processing. An imminent bankruptcy, angry customers, or other negative news about a corporation are examples of negative news. Oracle procurement software transforms these “events” into scores, and if the score is significant, Oracle flags the supplier with an email. Their supply chain design solution, Coupa, can also flag supplier risks based on single source or capacity constraints.

AI Drives Autonomous Decision Making:

A planned system transforms into a system of execution. This happens when the period between the formation of a plan and the actual execution of an order approaches.The goal is for delivery schedules apps to use machine learning to translate short-term desire signals into actionable plans. In other words, AI algorithms can move orders forward (for products with a longer shelf life) to balance the flow of commodities into distribution centers and storefronts.

Oracle, Manhattan Associates, Koerber, and Blue Yonder are all investing more in AI research and development for supply chain execution solutions. A transportation system is one example. They employ machine learning to predict how long a truck will take to deliver stuff. A warehouse management technology that can decipher a forecast of what ecommerce shoppers are most likely to purchase. Then they drop the appropriate work requests at the appropriate times.

Final Thoughts

The system is improving planning and is being used more and more for project execution, says Madhav Durbha, a renowned analyst. But keep in mind that AI can only help supply chains to a certain extent; it’s not like waving a magic wand and having all of your troubles vanish.

Blockchain Council offers artificial intelligence certification programmes which can aid AI Developers and artificial intelligence experts to excel in their respective field.

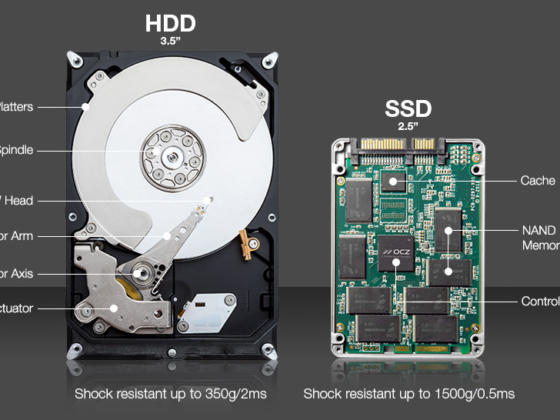

Also read: HDD and SSD drives: drive types and interfaces comparison